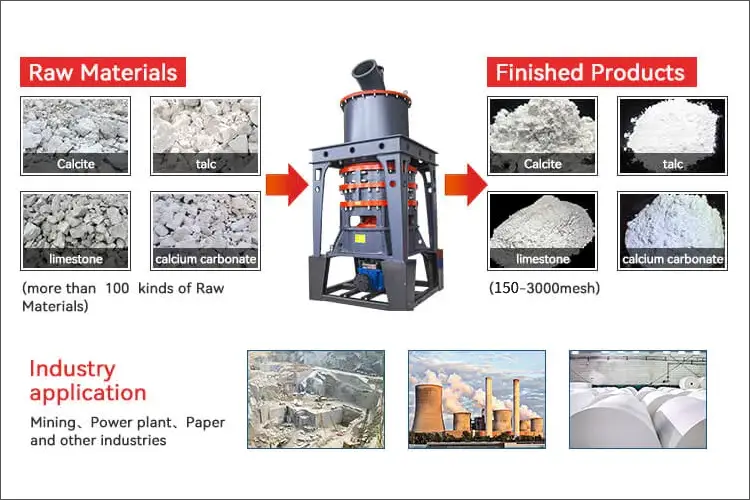

Talc powder mill (ultrafine mill) is mainly suitable for ultrafine powder processing of non-flammable and explosive brittle materials with medium and low hardness, Mohs hardness ≤ 6. Such as calcite, chalk, limestone, dolomite, carbon black, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomaceous earth, heavy More than 100 kinds of materials such as spar, gypsum, alunite, graphite, fluorite, phosphate rock, potassium ore, pumice, etc. The particle size of the finished fine powder can be adjusted arbitrarily between 325-2500 mesh (47-5 microns), and the output can reach 400-7500 kg per hour.

Working principle of talcum powder mill

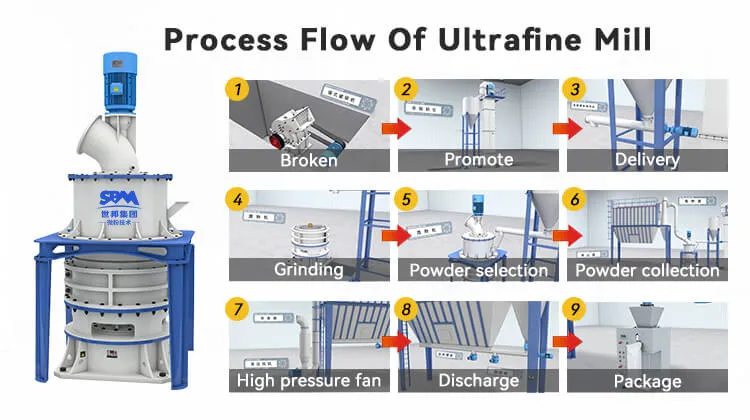

When working, put the material to be crushed into the machine from the hopper on the side of the machine casing, rely on the grinding roller device suspended on the plum blossom frame of the main machine, revolve around the vertical axis, and at the same time rotate itself, due to the centrifugal force during rotation, The grinding roller swings outwards and presses tightly on the grinding ring, so that the spatula scoops up the material and sends it between the grinding roller and the grinding ring, and the purpose of crushing the material is achieved due to the rolling and rolling of the grinding roller.

Wind separation process: After the material is ground, the fan blows the air into the main casing, blows up the powder, and is sorted by the analyzer placed above the grinding chamber, and the over-fine material falls into the grinding chamber for regrinding. The powder that meets the specifications enters the cyclone collector with the wind flow, and after being collected, it is discharged through the powder outlet, which is the finished product.

The air flow returns to the fan from the return air pipe at the upper end of the large cyclone collector. The air path is circular and flows under negative pressure. The increased air volume of the circulating air path is discharged through the exhaust pipe between the fan and the main engine, and enters the small cyclone collection. device for purification.

Performance advantages of talcum powder mill

1. Energy saving and high efficiency

Talc pulverizer (ultrafine pulverizer) has more than double the output of jet mill, stirring mill and ball mill when the finished product fineness and motor power are the same.

2. Long service life of wearing parts

Grinding rollers and grinding rings are forged from special materials, which greatly improves the degree of utilization. In the case of the same material and finished product fineness, the service life of the wearing parts is 2-5 times longer than that of the impact crusher and turbo pulverizer, generally more than one year. When processing calcium carbonate and calcite, the service life can reach 2 -5 years.

3. High safety and reliability

The talc pulverizer (ultrafine pulverizer) has no rolling bearings and no screws in the grinding chamber, so there is no problem that the bearings and their seals are easily damaged, and there is no problem that the screws are easy to loose and damage the machine.

4. High product fineness

Talc mill (ultrafine mill) product fineness can reach D97≤5μm at one time.

5. Environmentally friendly and clean

The talc pulverizer (ultrafine pulverizer) uses a pulse dust collector to capture dust, and a muffler to reduce noise, which is environmentally friendly and clean.

Factors Influencing the Price of Talc Powder Mill

There are many factors that affect the price of equipment, the main ones are quality, model, and market demand. The following is a brief analysis of the above three points.

1. Quality

The quality of equipment is a direct factor affecting the price. Good quality equipment has better performance and more stable operation. Of course, the price will be on the high side, as the saying goes, you get what you pay for.

2. Model

The same equipment, different models will also have certain differences in price. Due to different production scales, users have different requirements for equipment models, so the cost of purchasing equipment is also different, but when purchasing You should also focus on what suits you.

3. Market demand

When the supply of equipment in the market exceeds demand, the price of the equipment will rise, so that the market price of the equipment will increase. When the supply of equipment exceeds the demand, the market price of the equipment will drop to a certain extent.