Fluorite ore has a variety of colors. After processing, it is widely used in the two major industrial fields of chemistry and building materials. It can be made into anticancer drugs, preservatives, additives, refrigerants, cosolvents, etc.; it is also used in the production of glass, cement, ceramics, etc. Important added raw materials during processing.

There will be some other gangue minerals in fluorspar mines in nature, and only after flotation processing can more valuable fluorspar concentrates be obtained. What equipment is needed to process fluorite ore?

Fluorite ore crushing equipment

Jaw Crusher: The mined fluorite ore must first go through a preliminary coarse crushing treatment with a jaw crusher, the purpose of which is to achieve the initial dissociation of gangue minerals and fluorite. The choice of jaw crusher can better realize the crushing of fluorite ore, because of its outstanding structure and performance characteristics, usually manifested in the following points:

1. The internal structure is compact and the appearance design is beautiful, so it is small in size, strong in adaptability, light in weight, easy to operate and install, and reduces infrastructure investment by 20,000 yuan;

2. The crushing cavity is deep and the capacity is large, not only the crushing efficiency is increased by 2.5 times, but also the output is higher, meeting the production target of high efficiency and high output;

3. The quality is strong, there are few faults, and it is easy to maintain. It can also maintain high-efficiency and stable operation in harsh environments, and the annual maintenance cost can be saved by nearly 50,000 yuan.

Fluorite ore grinding equipment

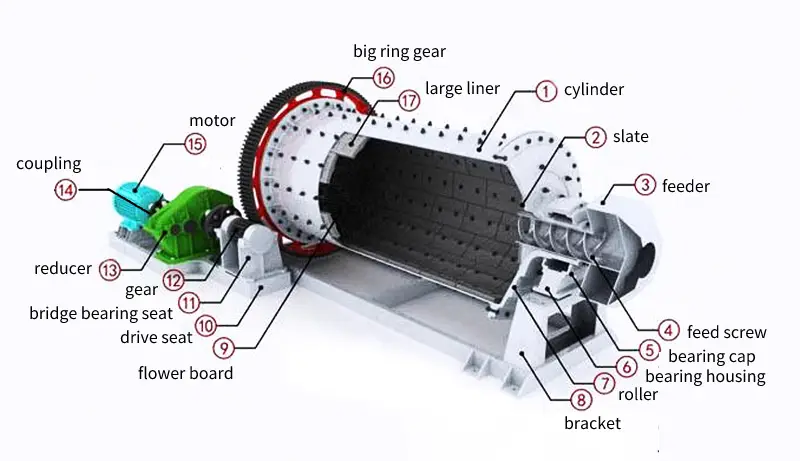

Fluorite ball mill: The crushed fluorite ore will be sent to the ball mill for grinding. Appropriate grinding fineness will help improve the final flotation accuracy. Generally, the grinding fineness of fluorite ore will be controlled at -74μm90%. As a special equipment for grinding fluorite ore, the ball mill has quite distinctive features, as follows:

1. The introduction of a new German grinding body design scheme, the grinding efficiency is increased by 60%, and the fluorite ore after grinding has uniform fineness and adjustable particle size;

2. The configuration of internal steel balls is scientific and reasonable, selectively grinding fluorite ore, saving energy consumption, reducing wear and tear, prolonging the life of steel balls by more than 3 times, and reducing energy consumption by 70%;

3. It is easy to operate, quick to install, and stable in operation. At the same time, there will be no dust, noise and other pollution during the operation of the equipment. After the exhausted smoke is filtered, it can fully meet the ideal standard.

Fluorite ore flotation equipment

Flotation machine: The flotation machine is the key equipment for fluorite ore processing. As long as reasonable chemicals are added to make it fully react in the flotation chamber, the final finished fluorite concentrate can be obtained. The equipment is produced by introducing advanced European technology, and its performance characteristics are very remarkable.

1. High efficiency and energy saving: the design of the flotation chamber is special, the mineralization fineness is more uniform, and the flotation is more efficient, and the energy saving of the single equipment is about 60%-70%;

2. Green and environmental protection: mineral processing backwater and flotation tailings have been rationally treated, not only backwater recycling, but also tailings will not cause any pollution to the environment, water flow, atmosphere, etc.;

3. Higher precision: The reagents and fluorite minerals can fully contact and react fully in the cavity, improving the flotation precision by more than 40%, and the finished fluorite concentrate has a higher grade.