Limestone mill

Limestone mill

The main component of limestone is calcium carbonate (CaCO3) with a Mohs hardness of 3. There are quicklime and slaked lime. After limestone is mined from limestone, it is crushed to form limestone particles, namely stone, sand, or further ground to form limestone powder. Limestone powder is widely used in building materials, highways, metallurgy, chemical industries and other industries.

Limestone grinding process

1. Feeding system:

The limestone in the receiving hopper enters the bucket elevator through a belt conveyor (plus iron remover), and the elevator sends the material to the raw material warehouse for grinding. A belt feeder is installed in the lower part of the raw material warehouse to evenly send the material to the industrial grinding mill for grinding.

2. Grinding system

The material is sent to the industrial grinding mill for grinding, and the finished product after grinding passes through the powder separator, enters the cyclone dust collector and the pulse dust collector, and is sent to the screw conveyor from the lower discharge port.

3. Finished product conveying system:

The discharge port of the screw conveyor is equipped with a pneumatic conveying system to transport the finished product to the finished product warehouse, and the excess gas is filtered by the dust collector on the top of the warehouse.

4. Dust removal system

The whole system is equipped with three pulse dust collectors, and air exhausts are installed at all dust-raising points to ensure that the whole system has no dust leakage and realize dust-free operation on site.

5. Control system:

The system is equipped with an intelligent PLC control cabinet and upper computer to realize the start-stop, monitoring, and interlocking linkage functions of all the equipment of the whole system, and reserves the DNS interface, which can realize remote control.

Recommended limestone industrial mills:

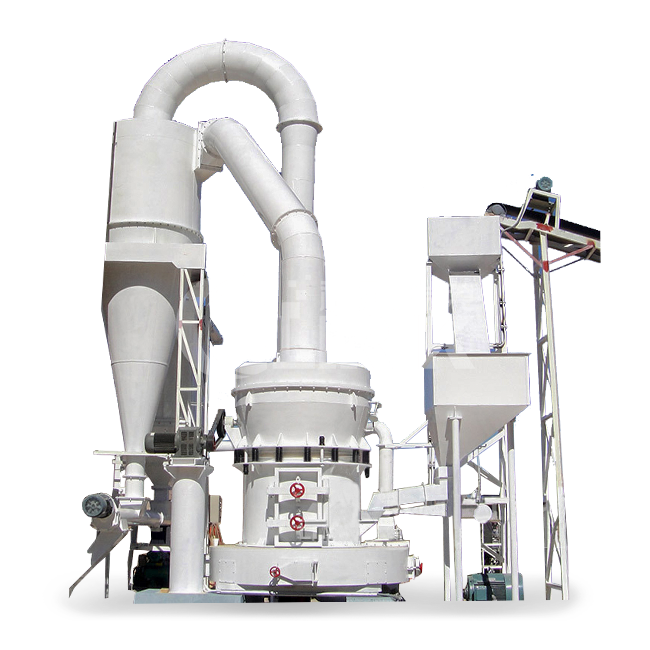

YGM Raymond mill

YGM Raymond mill

The upgraded version of the traditional Raymond mill, independently developed and produced by clirik. The output is 20%-40% higher than the traditional Raymond mill. The machine's wearing parts have stronger materials and longer service life. Low investment, simple operation, stable and environmentally friendly.

Final product fineness: 80-600mesh

Capacity: 1-40t/h

GET MORE

HGM ultrafine grinding mill

HGM ultrafine grinding mill

● High Efficiency

Under the same finished final size and the same motor power, the capacity of clirik HGM ultrafine grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

● Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill.

● High safety and reliability

● High fineness, flexible adjustment

Final product fineness: 300-2500mesh

Capacity: 0.2-45t/h

GET MORE

CLUM vertical roller mill

Application range: cement ultrafine powder processing, square stone processing, heavy crystal stone, grinding processing

Material: non-metallic mines such as square stone, marble, limestone, talc, heavy crystal, magnesia, raw lime, gypsum, slag, phosphate, etc

production capacity: 0.5-45t/h

The fineness of the finished product: 200-3000 meshes

Application areas of quicklime

Production fineness: 200 mesh D90

After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in block form and is used in water treatment, asphalt improvement, desulfurization, building materials, medicine and other industries.

Application areas of hydrated lime

Production fineness: 200 mesh D90

Quicklime becomes hydrated lime by absorbing moisture or adding water. The main component is calcium hydroxide Ca(OH)2, which is used in environmental protection, medicine, food and other industries.

FAQ:

1. Why should you buy limestone industrial grinding mill from us?

CE, ISO9001

factory sell directly

30 years experience, professional

2. What payment methods can we accept?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT, DDU, Express Delivery

Accepted Payment Currency: USD

Accepted Payment Type: T/T, L/C, Western Union