Introduction

Bentonite is a non-metallic mineral with montmorillonite as the main mineral component. Bentonite has good physical and chemical properties. It can be used as binder, suspending agent, thixotropic agent, stabilizer, purification and decolorizing agent, filler, feed, catalyst, etc. Widely used in agriculture, light industry, cosmetics, medicine and other fields.

Bentonite needs to be crushed and ground before it can be better used in the market. Its crushing equipment is usually jaw crusher or hammer crusher, and the grinding equipment needs to use Raymond mill.

With the different requirements for bentonite in many fields, the mining equipment industry is also constantly innovating and improving the pulverizer equipment to make it better in the milling of bentonite. In order to accelerate the development of bentonite resources and promote the improvement of bentonite production and processing technology, our company has developed a bentonite raymond mill based on the production of fine milling machinery for many years. It has a series of characteristics of high efficiency, low energy consumption and high powder output.

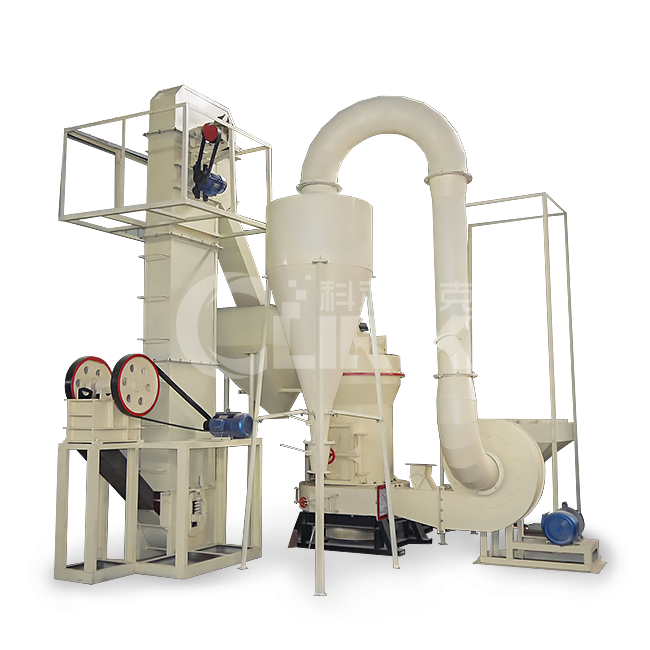

Bentonite Raymond Mill Pictures

Bentonite Raymond Mill Performance Advantages

1. Less wear and tear

The structure of the grinding rollers has been updated, so that the grinding rollers and the grinding roller shafts can complement each other and improve the durability of the grinding rollers. It can work under greater grinding force and higher running speed, reducing the wear and tear of wear parts.

2. The rotation is stable and the floor area is small

The main transmission device of the bentonite Raymond mill adopts a sealed gear box and pulley, which has stable transmission and reliable operation. The entire Raymond machine is a vertical structure, which occupies a relatively small area and is convenient for customers to operate.

3. Simple and reliable operation and convenient maintenance

The electrical system of the bentonite Raymond mill adopts centralized control, and the milling workshop can basically realize unmanned operation, which can save labor costs for customers and facilitate maintenance.

Bentonite Raymond Mill Working Principle

After the bentonite is crushed to the required particle size, the material is sent to the storage hopper by the elevator, and then sent to the main grinding chamber evenly and quantitatively through the vibrating feeder. The shovel of the grinding ring scoops up the material and sends it between the grinding roller and the grinding ring, and the purpose of grinding the material is achieved due to the rolling of the grinding roller.

The pulverized powder is taken away by the air flow of the fan, and is classified by the analyzer. The powder that meets the fineness enters the large cyclone collector through the pipeline with the air flow, and is separated and collected, and then discharged through the powder pipe to be the finished powder.

In the grinding chamber of the bentonite raymond mill, there is a certain amount of water in the material to be ground, heat is generated during grinding, the water vapor evaporates, and the pipe interfaces of the whole machine are not tight, the outside air is sucked in, which increases the circulating air pressure. In order to ensure the bentonite clay The Raymond mill works under negative pressure, and the increased airflow is discharged into the dust collector through the residual air duct, and then discharged into the atmosphere after being purified.

Bentonite Raymond Mill Manufacturers

CLIRIK is a mining machinery manufacturer specializing in the production of various grinding equipment, and has been committed to the research and development and production of bentonite Raymond mills for many years. A variety of new bentonite Raymond mills have been successfully produced. The particle size of the finished product is adjusted in the range of 80-600 mesh, so that the bentonite can be freely adjusted and processed according to the needs during the processing. It can also meet the needs of different industries and different fields for bentonite finished products, accelerate the improvement of bentonite production technology, and at the same time meet the needs of customers with different fineness and output.

How to choose a bentonite raymond mill

Before purchasing a bentonite Raymond mill, we must understand our actual production needs, our requirements for the fineness of the finished product, and the requirements for the output of the mill. Then according to the production needs, we consult the manufacturer of the pulverizer, and ask about the performance of various pulverizers, so that the manufacturer can recommend the appropriate model of Bentonite Raymond pulverizer for our needs. The specific purchase items are as follows:

1. When purchasing a bentonite raymond mill, we must choose a large-scale, large-scale and powerful raymond mill manufacturer.

2. We need to consult the basic performance of the pulverizer, the material of the wearing parts, whether the various parts of the pulverizer are genuine products, etc. Only by ensuring the quality of the pulverizer can the greater potential of the pulverizer be brought into play. In addition, we need to understand the installation of different types of mills, so as to calculate the specific investment cost.

3. The main reason we invest in the mill is its price, so we need to know how much a bentonite Raymond mill costs, and then we can choose a good model and understand the configuration of the equipment according to the model.

4. Some mill manufacturers in the market will attract customers with low prices, so when we buy bentonite Raymond mills, we try our best to visit the manufacturers on the spot. To see if the manufacturer has the production capacity, this is another layer of guarantee for the purchase of equipment.