Fly ash is a tiny ash particle discharged during the combustion and cooling of fuel (mainly coal powder) at high temperature, and its particle size is generally between 1-100 microns. Due to the adhesion of some particles during melting, the surface is rough and the edges and corners are mostly honeycomb composite particles. After being processed by a pulverizer, it is applied to the fields of industry and chemical industry.

What are the uses of fly ash?

1. Making concrete and cement

After sorting and grinding, fly ash can be used as a partial substitute for concrete raw materials. Different mixing amounts will affect the hardening level, strength, drying shrinkage and other characteristics of concrete. The technology of making cement with fly ash has been compared Mature, its content in the cement made can reach 75%.

2. Making building material brick products

Raw materials such as fly ash are processed through a series of processes to make different concrete blocks, such as aerated concrete bricks, small hollow blocks of fly ash concrete, fly ash bricks, etc.

3. Used in chemical industry

High-purity alum can be extracted from fly ash, which can be used to synthesize bauxite, and can also be used to produce non-oxide ceramic material SiC powder. After a certain refinement of fly ash, it can be made into polymer filling materials, which can be used for Synthetic materials are modified.

4. Make agricultural fertilizer and improve soil

Fly ash is rich in trace elements, such as silicon, boron, sulfur, zinc, copper, calcium, magnesium, iron, etc. It is loose in texture and can significantly improve soil structure. Adding appropriate amount of additives according to scientific formula can make compound fertilizer.

How to classify fly ash fineness?

How to classify fly ash fineness? The finer the fly ash, the better? It is mainly graded by fineness, there are first grade, second grade and third grade. The finer the fly ash is, the better it is. The pozzolanic reaction is relatively rapid and complete, so the higher the activity, the higher the strength of the concrete. In addition , and the particle size difference of cement, the combined use of the two can fill the gaps with each other, so that the void ratio of the mixed system composed of the two will be reduced, and the water demand ratio will be lower.

● The primary fineness refers to the sieve residue of 45 micron square hole sieve is not more than 12%.

● Secondary fly ash requires a 45-micron square hole sieve residue not greater than 25%.

● Class 3 fly ash requires a 45-micron square-hole sieve margin of not more than 45%.

Fly ash fine grinding process

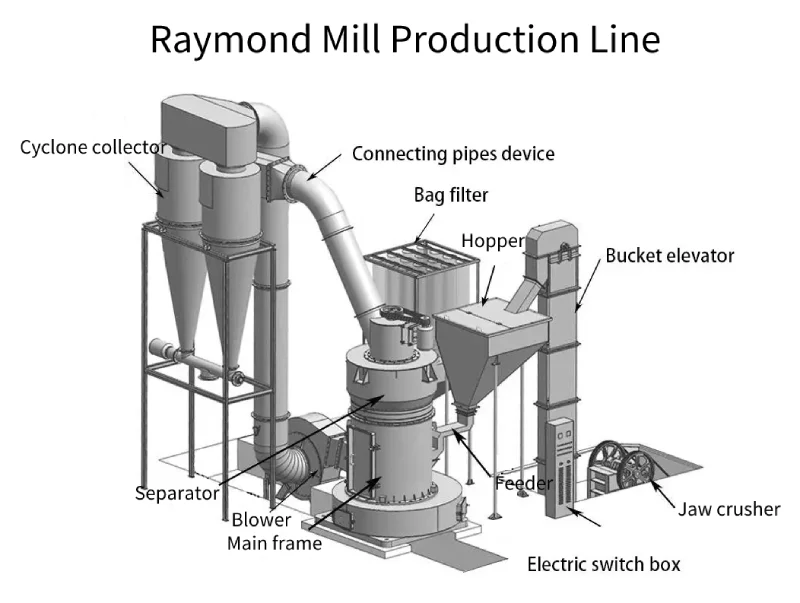

Processing technology: fly ash→jaw crusher (selected according to the size of raw materials)→bucket elevator→electromagnetic vibrating feeder→Raymond mill→powder separator→dust collector→finished products are put into storage after passing the test.

Which equipment is better for processing ultrafine fly ash?

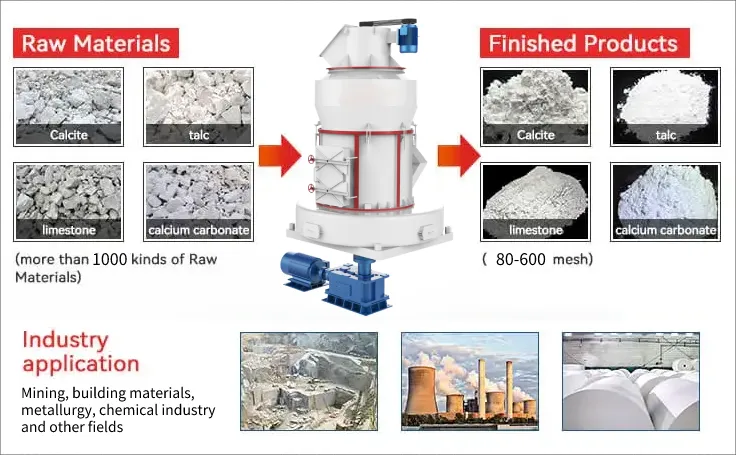

Ultra-fine fly ash is not a first-class fly ash, so it cannot be defined accurately, but generally speaking, it should be finer. There are many types of ultra-fine fly ash processing equipment in the market, but YGM high-pressure Raymond mill is relatively Comparatively speaking, the performance is good in all aspects. According to the actual situation of users using the pulverizer for many years, and in response to the needs of industry development, a new product is designed. The finished product fineness can be anywhere between 80-1000 mesh (13-180 microns). Adjust to meet the fineness requirements of ultra-fine fly ash.

1. The spring booster device increases the grinding force.

2. Under the condition of the same output and fineness, the energy consumption of the system is reduced.

3. The powder classifier is designed in a modular way to meet the needs of different fineness.

4. Frequency conversion and speed regulation of powder classifier, fine grading of products.

5. New sealing structure, long refueling and maintenance cycle, more energy-saving.

6. Pulse dust removal can realize automatic dust removal.