After the crustal movement thousands of years ago, the ancient riverbed was uplifted, resulting in sand and stone mountains, and the river pebbles generally came from this. Experienced the impact of flash floods, continuous extrusion and friction in the process of moving water. The surface of the river pebble is smooth and clean, the average content of SiO2 is 85%, the ideal compressive strength can reach more than 300MPa, and the comprehensive hardness is more than 7 degrees Mohs. It has good compression resistance, wear resistance and corrosion resistance, and is an ideal and widely used machine-made sand raw material.

Process flow of river pebble processing and production

The river pebble processing production line produced by CLIRIK perfectly matches the characteristics of a single machine and gives full play to its very high efficiency. It has the advantages of large production capacity, stable operation, uniform discharge particle size, good particle shape and less dust.

The first stage: primary crushing

The raw material passes through the silo, is evenly fed by the vibrating feeder, and transported to the jaw crusher for primary crushing. The primary crushed material and the fine material screened by the vibrating feeder are transported to the transfer material together by the belt conveyor. heap.

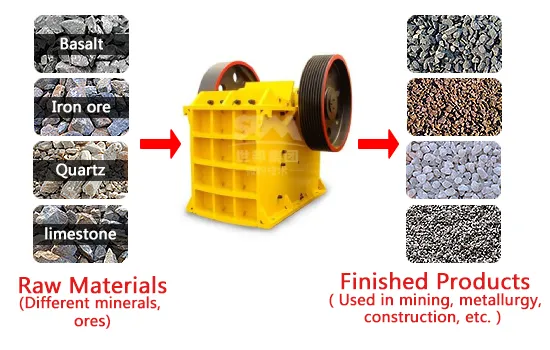

Jaw Crusher

The jaw crusher is mainly used for medium-sized crushing of ore and bulk materials. It can crush materials with a compressive strength of up to 320Mpa. There are two types: coarse crushing and fine crushing. CLIRIK has PE and PEW series jaw crushers, the product specifications are complete, the feeding particle size is 125mm ~ 1020mm, the ideal single machine output is up to 800t/h, it is the ideal equipment for primary crushing.

Sturdy structure and stable performance: It adopts the world's advanced technology, Baosteel high-quality steel, American Timken bearings, heavy-duty eccentric shaft, and finite element analysis technology to make it strong in structure, stable in performance and long-term operation.

Large crushing ratio and high output: heavy-duty sheave and flywheel, optimized jaw plate, make the crushing force larger. The "V" design makes the feeding port match the actual, the crushing cavity is deep and there is no dead zone, and the output is higher.

Easy operation and energy saving in operation: Hydraulic lubrication and wedge adjustment make the operation more convenient and flexible, and the lubrication is more convenient. The energy saving of a single machine is 15% to 30%, and the energy saving of the system is more than doubled.

The second stage: medium and fine crushing

The conveyor belt conveys the material of the transfer pile evenly to the cone crusher for medium and fine crushing, and after crushing, it is screened by a circular vibrating screen. Larger particles are returned to the cone crusher to be crushed again. The medium-sized materials are sent to the sand making machine for fine crushing and shaping. Qualified materials of particle size are cleaned by sand washing machine as final products.

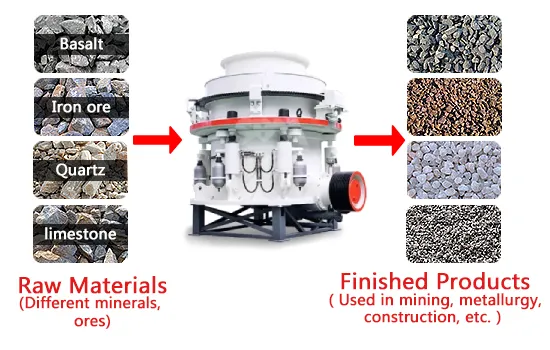

Multi-cylinder cone crusher

Multi-cylinder hydraulic cone crusher is a new generation of high-efficiency hydraulic cone crusher launched on the basis of nearly 20 years of crusher research and development experience, combined with advanced technology at home and abroad, after several generations of product development and application. On the basis of the traditional multi-cylinder hydraulic cone crusher with the main shaft fixed, the eccentric sleeve rotating around the main shaft structure and the principle of lamination and crushing, the HPT series has made a breakthrough in the optimization of the equipment structure, which has significantly improved the performance and crushing capacity of the equipment. The designed hydraulic lubrication system ensures the reliable operation of the equipment, and the operation control is more intelligent and humanized.

Higher efficiency of structural upgrade: On the basis of the unique structure of fixed main shaft and eccentric sleeve rotating around the main shaft, the equipment has further optimized the design of transmission rotating parts and lubrication and sealing structure. Small size, high efficiency and low noise.

The third stage: fine crushing and shaping

After the medium-sized materials are sent to the sand making machine for fine crushing, they are screened by a circular vibrating screen. The larger-sized materials are returned to the sand making machine for crushing again. The qualified products are sent to the storage pile by the belt conveyor for storage, and the fine materials are sent to the sand washing machine Machine cleaning.

VSI5X series new type sand making machine is a new generation product with a number of independent property rights developed on the basis of VSI series sand making machine introduced by our company. It integrates three crushing modes and has become the core equipment of the machine-made sand industry.

It is used in sand and gravel yard, mixing station, dry mortar, quartz sand, construction waste crushing and other industries, and provides high-quality sand and gravel aggregate for highways, high-speed railways, high-rise buildings, municipal, hydropower dam construction, and concrete mixing stations.

Stage 4: Finished Sand Washing

After the material fed into the sand washing machine is cleaned by the sand washing machine, it is conveyed by the belt conveyor to the storage pile as part of the final product.

XSD series sand washing machine, commonly known as wheel-bucket sand washing machine, is a high-efficiency sand washing equipment developed and produced by Shanghai Shibang Machinery using advanced technology at home and abroad, combined with the actual situation of the domestic sand and gravel industry.