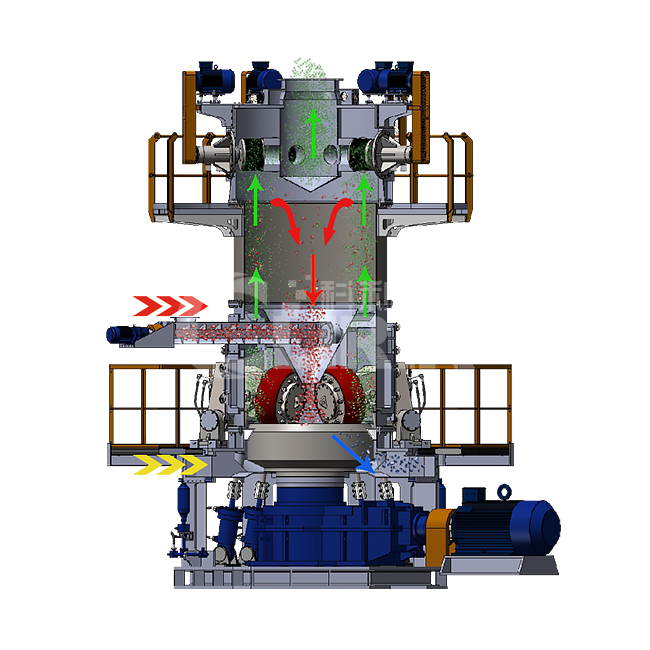

As the mainstream equipment for grinding powder processing, vertical mills have a direct relationship with the interests of enterprises in their production and operation links. Vibration produced by the vertical mill not only damages the equipment, but also causes the instability of the table time and affects the output due to frequent roll-up and roll-off. The vibration of the vertical mill is related to many factors such as transmission, material layer, foreign matter, roll surface, grinding disc, particle size, pressure and so on.

1. Vibration caused by transmission

The transmission part of the vertical mill includes a motor, a coupling, and a reducer. Any failure of any link can cause vibration. If the coupling installation accuracy is insufficient, that is, the alignment error is large, it will cause vibration dominated by axial vibration; if the motor rotor and stator do not coincide, the alternating magnetic field will pull the rotor back and forth with the change of the magnetic field direction, thus Causes axial vibration; damage to the reducer bearing, broken gear teeth, etc. will cause the vibration of the mill.

2. Vibration caused by unstable material layer

When the material layer is unstable, the distance between the grinding roller and the grinding disc is constantly changing, and the grinding roller is constantly high and low, causing the mill to vibrate. The material is too dry or too fine, the height of the retaining ring is not suitable, the feeding is unstable, or the flow rate of the material on the grinding disc is too fast, which will cause the material layer to be unstable.

3. Excessive particle size of the material block causes vibration

If the particle size of the raw material is too large, if it exceeds the thickness of the material layer, it will suddenly lift up and fall down when the grinding roller passes, causing the mill to vibrate. This type of vibration is determined by the number of large pieces and the fragility of the material.

4. Excessive iron causes vibration

When foreign matter such as iron block enters the mill, the grinding roller cannot crush it, causing the grinding roller to fluctuate and cause the mill to vibrate; if the foreign matter circulates in the system, it will cause vibration during the cycle time. Near the retaining ring, the vibration frequency is the product of the mill speed and the number of rollers.

5. Out-of-round grinding roller causes vibration

The grinding roller wear-resistant layer of the vertical mill has slag or lumps, the grinding roller will be out of round, and it will suddenly rise and fall every time it rotates, forming a regular vibration.

6. The grinding disc is broken or severely peeled off

When the grinding disc liner is broken or severely peeled off, the grinding disc will be uneven, and the grinding roller will suddenly sink every time it arrives, causing vibration. The vibration frequency is the product of the speed of the mill and the number of rollers.

7. Vibration caused by improper operation

When the wind speed of the wind ring is too high, the external discharge of the mill is reduced, and the material that needs to be circulated is turned over to the grinding table. Too much powdery material forms an unstable material layer, the pressure difference inside the mill rises, and the vertical mill vibrates; The grinding performance is poor, the speed of the separator is too high, and the fine powder returning to the grinding disc is too much, causing the material layer to be unstable, the pressure difference in the mill rises, and the mill vibrates. This kind of vibration has a great relationship with operation, and the period of vibration is related to the adjustment frequency of operation.

8. Roll pressure is too low

When the roller pressure is too low, it is difficult to crush the bulk material, the grinding roller beats the grinding disc with fluctuations, and vibration is inevitable.

The above explains the reasons for vibration in the production of vertical mills. If you encounter such failures, you should find out the reasons and corresponding solutions to resume normal production.