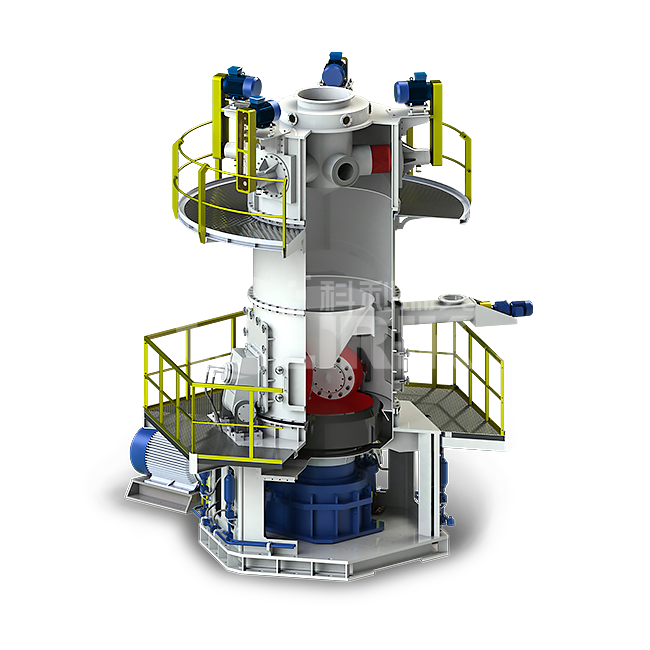

Vertical mill plant introduction

Vertical mill can grind coal, marble, granite, kaolin, hard coke etc. so it is also called vertical grinding mill or vertical roller mill. CLIRIK vertical mill and vertical roller mills are the best choice for your powder plant.

Over View of vertical mill overview:

China supplier about Vertical mill:

We are a leading manufacturer of Vertical mill in Shanghai, China. As a professional manufacturer of this kind of machine, we have been in this line for many years, and now our products spread over the world for the good quality and competitive price.

Types of Vertical mill:

1. Finished powder products are in the 325meshs -3000meshs, and yield can be up to 0.5-12 tons per hour. There are five types of Shanghai CLIRIK HGM series vertical mill; they are HGM80, HGM90, HGM100, HGM100A and HGM125.

2. Finished powder products are in the 20meshes-325meshes, and yield can be up to 1-20 tons per hour. There are also fine models of this type vertical coal mill in CLIRIK, they are YGM7815, YGM8314, YGM9517, YGM4121 and MTM1600.

Detailed Product Description about Vertical mill:

Vertical grinding mill is mainly applied to grind non-inflammable, non-explosive and brittle materials with Mohs’ hardness under nine. Such as calcite, chalk, limestone, dolomite, kaolin, gypsum, and talc etc, totally more than 100 kinds of materials. Product fineness can be controlled between 20~3000 mesh

Comparable with ball mill, Vertical mill has features of low cost, high capacity, easy operation.

Production Line Configuration of Vertical mill:

The whole set HGM Vertical grinding mil consists of hammer crusher, bucket elevator, storage hopper, vibrating feeder, vertical mill, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems

Working Principle of Vertical mill:

The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial through plunger. After crushed by hammer crusher, the big materials become small ones and are sent to storage hopper by elevator and further sent to the middle of first dial evenly by the electromagnetic vibrating feeder and feeding pipe. The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings. The high pressure centrifugal blower will inhale air from outside and blow the crushed materials to classifier. The rotating turbo in the powder concentrator will make the coarse powder return to the mill and reground, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it. The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

Technical Data of Vertical mill:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1300 | |

| Ring Number(PCS) | 3 | 3~4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24~32 | 27 | 34~36 | 40~44 |

| Main Shaft Speed(r.p.m.) | 230~240 | 200~220 | 180~200 | 135~155 | |

| Input Size(mm) | ≦20 | ||||

| Finished Size/um(mesh) | 5-47(325~2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size (L*W*H, m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 14*9*10.25 | |

| Motor Power(KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

Technical Data of YGM/ MTM vertical mill:

| Type | Roller | Max. feeding size(mm) | Fineness of product(mm) | Output (t/h) | Power of machine(KW) | Size(mm) | ||

| No. | Dimension(mm) | Height(mm) | ||||||

| YGM7815 | 3 | 260 | 150 | 15 | 0.613-0.033 | 1-3 | 18.5 | 4300*3500*5100 |

| YGM8314 | 3 | 270 | 140 | 20 | 0.613-0.033 | 1.2-4.6 | 22 | 5300*4100*5200 |

| YGM9517 | 4 | 310 | 170 | 25 | 0.613-0.033 | 2.1-5.6 | 37 | 7100*5900*7900 |

| YGM4121 | 5 | 410 | 210 | 30 | 0.613-0.033 | 2.8-10.5 | 75 | 9200*7250*9700 |

| MTM1600 | 6 | 440 | 270 | 35 | 0.613-0.033 | 5-20 | 132 | 12550*5700*8350 |

Performance and features of Vertical mill:

1. High efficiency

Under the same final size and power, the product capacity of micro powder grinding mill is twice than jet mill and agitation mill.

2. Long lifetime of wearing parts

The roller and ring are made of special material, which improve the grinding efficiency a lot. For same material and final size, the lifetime of its wearing parts can reach to more than one year, about 2-5 times as long as that of vertical impact crusher and turbo-mill. Especially when handling calcium carbonate and calcite, the lifetime can reach 2-5 years.

3. High safety and reliability

There are no rolling bearings and bolts in grinding cavity, so problems caused by bolts shedding or wear of bearings and seal components will never happen.

4. High fineness of products

The product fineness can reach D97≤5μm.

5. Environment friendly

The application of DMC-120 pulse dust collector and muffler reduce the pollution and noise of the dust, which has reached national environment protection standard