Serpentine and Serpentine powder grinder machine in China:

Serpentine is a general term for an aqueous magnesium-rich silicate minerals, such as antigorite, lizardite, chrysotile, etc.. Their color generally is greenish hue, but there are light gray, white or yellow. Because they tend to be green and white, so named, like snakeskin. The serpentine structure is often curled like fiber. This serpentine often cited as asbestos. Massive or fibrous serpentine will have a shiny, massive, such as wax, fibrous, such as silk. Serpentine mainly used as a firing FCMP, steelmaking flux, refractories, building plate, engraving process, to extract magnesium oxide and porous silicon oxide, also used in medical, purification fluorine water, manufacture of fluoride tablets . China is rich in erpentine, good texture. The main mineral is in Donghai County, Jiangsu Province, Shan Zuo Jiangxi Yiyang Zhangshuduan, Xinyang, Henan Crouching Tiger, Ningqiang County, Shaanxi Province, black lumber Lueyang Jianchaling and Mianxian Yasuko Hill.

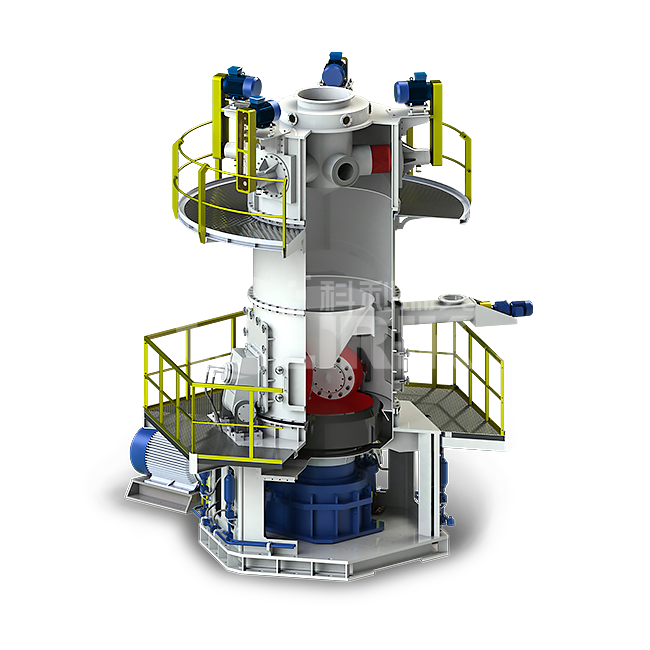

The whole set Serpentine powder grinder machine consists of:

1). Hammer crusher, bucket elevator, storage hopper, vibrating feeder,

2). Main unit, inverter classifier, cyclone collector, pulse deduster system,

3). High pressure positive blower, air compressors and electrical control systems.

How does Serpentine powder grinder machine work?

1) After crushed by hammer crusher, the large materials become smaller pieces and are sent to the Serpentine powder grinder machine.

2) When the Serpentine powder grinder machine is at work, the granulated materials are crushed and grinded by the rollers into particles below 47micron.

3) The high-pressure air blower constantly inhales air within the Serpentine powder grinder machine.

4) Along with the high speed airflow, micronized materials are brought to the classifier.

5) The qualified particles are screened and driven into the cyclone powder collector, finally exit from the discharging valve at the bottom;

6) A small proportion of the fine powders, with airflow, moving to the dust cleaner. Filtered clean air will be emitted from the air outlet of muffler in the end.

Technical data of Serpentine powder grinder machine:

| Model | HGM80 | HGM90 | HGM100 | HGM100A | HGM125 |

| Ring Diameter(mm) | 800 | 930 | 1035 | 1035 | 1300 |

| Ring Number (PCS) | 3 | 3-4 | 3 | 4 | 4 |

| Roller Number(PCS) | 21 | 24-32 | 27 | 34-36 | 40-44 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 180-200 | 135-155 |

| Input Size (mm) | ≤20 | ||||

| Finished Size (um) | 5-47(325-2500) | ||||

| Capacity (t/h) | 0.5-4.5 | 0.6-6.5 | 0.7-7 | 1-8.5 | 1.5-12 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 18*4.6*8.6 | 14*9*10.25 |

| Motor powder (KW) | 145-165 | 185-204 | 263 | 263-290 | 380-430 |

Note: This specification is just referencing, any changes are subject to the products.

Features and advantages of Serpentine powder grinder machine:

Serpentine powder grinder machine Under the same finished final size and the same motor power, the capacity is twice as much as jet mill, mixing grinder and ball mill. The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime of Serpentine powder grinder machine can reach 2-5 years. As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness of Serpentine powder grinder machine can reach D97≤5μm. The application of pulse deduster and muffler greatly alleviates the dust pollution and noise.

Shanghai clirik machinery co., LTD.

Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machine.please do not hesitate to contact us.

Phone: 0086-21-20236178;86-18918057603

Contact person: lily wang

Email:sales@clirik.com; lilywang@clirik.com

Online consulting: http://www.saico.net ; http://www.grinding-equip.com;

http://www.powder-grinder.com; http://www.powder-mill.net;

http://www.fine-mill.net; http://www.stone-mills.com

Address: No.19 Fuqing Rd, Pudong New Area, Shanghai201201, China.